The Advanced Technology Behind Our Liquid Filling Solution

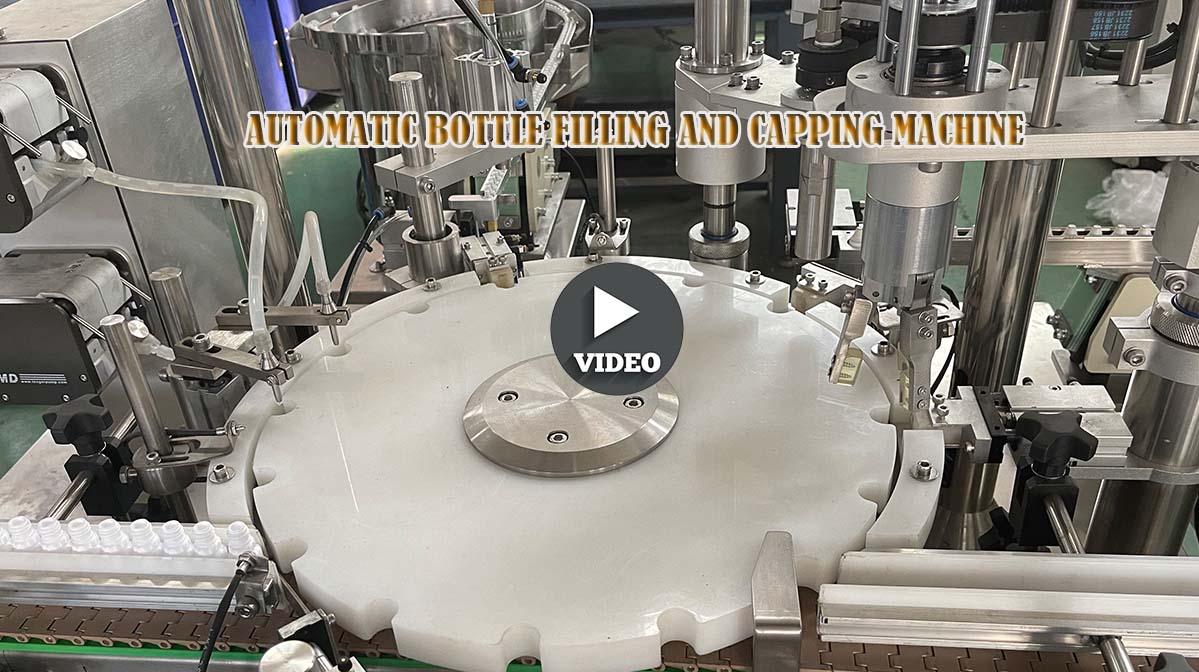

Automatic Chemical Liquid Pesticides Filling Machine

The automatic filling machine is designed for the precise dispensing of liquid products such as pesticides and syrups. It is versatile, accommodating bottles of various shapes, making it indispensable in pharmaceuticals, food, and cosmetics industries. The filling process is seamlessly executed under the precise control of a PLC program displayed on an intuitive touch screen. This ensures stable and reliable operation, high efficiency, and remarkable adaptability. Notably, the filling volume specifications can be effortlessly adjusted within minutes, reflecting its advanced technology and sophisticated design, eliminating the risk of dripping.

A distinguishing feature of this machine lies in its ability to customize the bottle volume according to the client's bottle and cap size preferences. This flexibility ensures the machine's compatibility with a diverse range of packaging requirements.

Key Features:

* Adherence to International Standards: All electrical controls comply with international standards, utilizing imported components. The machine features frequency control, allowing for continuous speed adjustment.

* Anti-Drip Filling Head: The machine is equipped with a special anti-drip filling head that enhances precision and minimizes the risk of dripping during the filling process.

* Automatic Shutdown: The machine incorporates a 'no bottle, no filling' mechanism, ensuring efficiency by preventing filling when no bottle is present. This extends to 'no bottle, no capping,' and an automatic shutdown feature.

* Optimized Filling Head Placement: The filling head is strategically positioned two-thirds into the bottle during the filling process. This design prevents liquid impact bubbles, ensuring a smooth and controlled filling process.

* Magnetic Torque Type Capping Manipulator: The capping mechanism employs a torque-adjustable magnetic torque type manipulator, featuring a non-contact clutch. This ensures minimal loss, automatic correction of the cap, and a superior capping effect compared to conventional methods.

* Overload Protection and Alarm Prompt: The machine is equipped with overload protection and an alarm prompt function, enhancing safety and reliability.

* PLC Control with Color Touch Screen: The entire system is efficiently controlled by a PLC, with a user-friendly color touch screen making the operation simple and intuitive.

* Stainless Steel Construction: The majority of the machine is constructed from SS304, ensuring durability and meeting the GMP standard for special materials.

* Dust Cover Compatibility: The filling and capping machine can be equipped with a dust cover, enhancing its sanitary features.

For further details on our automatic pesticides filling, capping, and labeling machine line, please do not hesitate to contact Higee Machinery. We are committed to providing cutting-edge solutions tailored to meet your specific needs.