For PET bottle, Hot filling VS aseptic filling

For PET bottle, Hot filling VS aseptic filling

Juice Hot filling Machine does filling in hot temperature. After the liquid such as juice, milk, tea, coffee is instantaneously sterilized by UHT, the temperature is cooled to 85-92°C for filling. At the saHot filling does filling in hot temperature. After the liquid such as juice, milk, tea, coffee is instantaneously sterilized by UHT, the temperature is cooled to 85-92°C for filling. At the same time, the beverage needs to be refluxed to maintain a constant filling temperature which sterilizes bottles and caps.

me time, the beverage needs to be refluxed to maintain a constant filling temperature which sterilizes bottles and caps.

PET aseptic cold filling production lines generally adopt UHT ultra-high temperature sterilization process. Generally the temperature reaches 138-145℃. The time is between 1 and 30 seconds. The sterilization method is sterilized in high temperature and short time.

Compared with the two filling processes, the biggest difference is the different heating time of the beverage. Aseptic filling only uses UHT ultra-high temperature instantaneous sterilization. The heating time of materials is short. The smaller the loss of nutrients is, the better is the quality and taste are. The sterilization effect can be guaranteed under high temperature conditions. While the sterilization used in hot filling The method keeps the material in a high temperature state for a long time, which seriously affects the taste, color and heat-sensitive nutrient content of the product.

Bottle and caps Crystalline heat-resistant PET bottle (capable of withstanding 85℃-92℃ high temperature without deformation) and special heat-resistant bottle cap Ordinary PET bottle (maximum heat-resistant temperature 60℃) and standard cap Liquid requirements Keep the beverage at high temperature for a long time and add preservatives After sterilized liquid via UHT, cool to room temperature Sterilized bottles Rinse with ozone water, chlorinated water Sterilize by soaking or spraying with disinfectant Sterilized caps Use UV irradiation or simply rinse with chlorinated water Sterilize by soaking or spraying with disinfectant Filling environment One hundred thousand grade purification workshop 100-level purification in the filling area; 10,000-level purification in the filling room Filling machine The filling system adopts external circulation method and requires CIP The non-contact filling method is adopted. A complete CIP and SIP system is required. There are strict on the filling space requirements and the delivery method of the external packaging materials. After filling Need to invert the bottle sterilization chain and spray cooling equipment Operation The process environment is simple to operate, and the quality control management is relatively loose The process environment operation is extremely complicated, and the quality control management requirements are extremely strict Operational risk Impact on product flavor

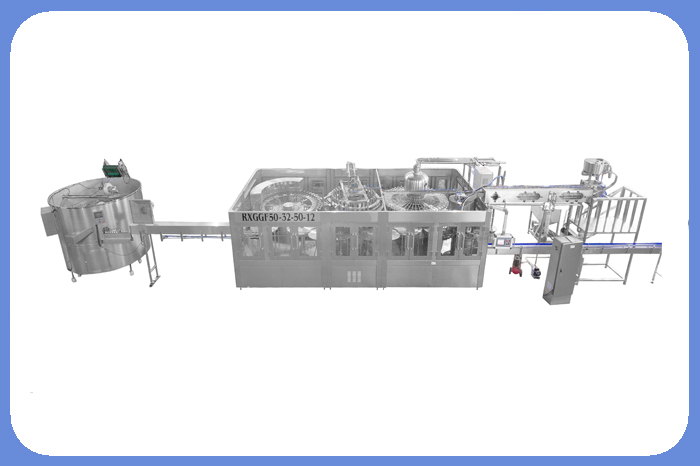

Higee Machinery is the profesionable manufaturer and exporter for the drink and beverage filling packing sealing machine. Welcome for any inquiry if you want to start these business. Technology

Hot filling

Aseptic filling

No

Small

Big

Some

A little